|

|

|

#16 |

|

Tys

|

Neat...it's nice to know someone else did that. I know KWA does it straight from the factory for their mechboxes....after seeing several of their mechboxes I though of doing the same.

Granted, I usually shim the bevel "fixed" in place laterally...but on occasion I've reshimmed it to be further to the "right" of centerline if the mechbox didn't sound right. Tys |

|

|

|

|

|

#17 |

|

Wow. I did that on my C8 as well. I found that I couldn't seem to adjust the motor height properly to minimize gear noise. After thinking about it for a while, I put a couple of shims on the bottom axle of the bevel gear to ensure the ARL would always catch properly, and no shims on the other side. It allows the bevel gear to move side-to-side a bit, which still meshing with the spur gear correctly. And it now the pinion and bevel gear mesh perfectly and it reduced the gear sound in my gun significantly.

I wasn't sure this was a correct way of doing things, but figured I'd try it out. I have some spare gears kicking around if stuff went wrong. But now after 2 games with my trusty carbine, it's performed admirably and still sounds nice and smooth. I'm glad to hear that I wasn't totally out to lunch trying this technique that seems quite contradictory to the regular views on shimming...

__________________

|

|

|

|

|

|

|

#18 | |

|

Quote:

Or putting no/little shims on the bevel? Sorry, I don't believe I've been into a KWA mechbox yet.

__________________

Ronin 49 Team Member |

||

|

|

|

|

|

#19 | |

|

Quote:

Well if you ever shim the top half of the bevel I'd be curious to see if the noise changes!

__________________

Ronin 49 Team Member |

||

|

|

|

|

|

#20 |

|

I normally shim the bevel gear so there's no play. But time and time again with this mechbox, I tried and it was always noisy. I thought about it a bit, and figured a BIT of play would allow the gears to mesh better. And it seems to have worked. And technically, once the pinion and bevel gear connect, there will be no lateral play.

And as I said, if it causes premature wear and gear issues, I have spare gears and a spare motor lying around that I can replace them with... But so far after about 2500 rounds (2000 in-game, 500 test-firing), it's all good and running smoothly.

__________________

|

|

|

|

|

|

|

#21 | |

|

Quote:

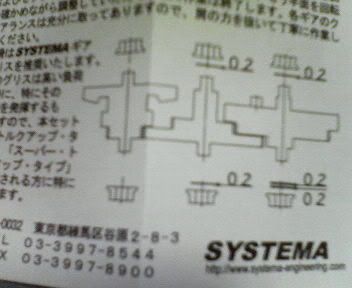

systema also recommend not to put shims on the bevel gear (image is for reference only)

__________________

CLICK HERE TO MY WEBSITE Last edited by Tirador; March 27th, 2009 at 16:25.. |

||

|

|

|

|

|

#22 |

|

Tys

|

I sprinkle magic pixie dust on my mechbox and then leave it out under a rainbow...works perfectly after that.

Edit: Sorry, not the most helpful post...it's budget time and I've been staring at excel sheets all day.... I put together a few mechs with "loose" bevels...and it seemed to work. But I reverted back to shimming it in place just out of comfort and peace of mind. As you're shimming, you can get a sense of how far away from the right side (and thus closer to centerline) by how many shims are going on top of the bevel gear....if I end up with more than two...I'll take a good look to see how far off things are. I suppose that if your grip is wonky (i.e. poorly made/molded...read Dboys) you're motor will be completely out of alignment to begin with...making this a futile exercise. Then you'd need pixie dust AND lucky charms... Tys Last edited by m102404; March 27th, 2009 at 16:16.. |

|

|

|

|

|

#23 | |

|

Quote:

There can be no lateral play in the downward direction for the bevel gear (it 'sits' on top of the pinion). But if there's room between the top of the bevel gear and the top bushing, there's lateral play there. Now maybe your bevel gear sitting lower than a normal one, so by not shimming the top half you allow the bevel to move into the 'correct height' when the pinion gear and motor are installed? By shimming the top half you are essentially not allowing the bevel gear to self correct it's height when the motor/pinion are installed. Note: If you look at Tirador's system diagram pic, that's my up/down reference. Tys, I think I'm going to have to borrow some pixie dust - my new SPR has magical little gremlins in there that won't come out!

__________________

Ronin 49 Team Member |

||

|

|

|

|

|

#24 |

|

On a totally unrelated note, my box of madbull BB's just arrived for my testing! I skipped classes all day just so I could be home to receive them so I could get my testing done tomorrow, haha.

6 different madbull BB weights, at least 2 different FPS ranges depending on time (~300 and ~400 fps), and 1 large 300ft long warehouse :smile: It's for a university project - which BB weight travels further (w/ properly tuned hopup). I also have to do the theoretical number crunching to see if my testing tomorrow matches my model. Should be neat!

__________________

Ronin 49 Team Member |

|

|

|

|

|

|

#25 |

|

Tys

|

You bastard! 300ft indoor....

I have all the weights but limited space!!! Killing me. On a similar/non-related note, I'm taking some M16 509mm barrels and am going to set it up so I can chop an inch off at a time and rechrony...I'll hit the major barrel lengths down to 7" or 6.5"...record FPS readings and then graph it out. Perfectly good reason to destroy perfectly good barrels....LOL |

|

|

|

|

|

#26 |

|

I wanted to get some of the heavier weights too but I figured I should just grab what is most commonly used...$160 later!

I'm testing: .20, .23, .25, .28, .30, .36 I've been wanting to do this BB weight vs range test forever to actually end the debate, but I'm kinda lazy. We had a project that was of our own choice and this worked out nicely! I got to do something I'm actually interested in and get marks for it. The prof especially loved the fact that I was doing imperical testing to see if it fit my theory/model. For your barrel length testing, are you using just a full cylinder? I'm also curious to see extensive testing done between properly matching cylinders with barrels (ie. ported vs not). I've only quickly tested that twice - once with a ~15fps difference (ie. 15fps drop using a full cylinder on an m4) and the other no noticable difference. Maybe you could get your hands on a V3 and a prowin hopup unit so you can just test it outside of the gun and simply chop the barrel down every inch - no need to take apart anything and eliminates a lot of disassembly/assembly variability!

__________________

Ronin 49 Team Member |

|

|

|

|

|

|

#27 |

|

Actually, I do have one shim on the top of the bevl gear to . Without the motor installed, there's a bit of lateral play. I tested by installing the grip to the box, then the motor. And I set the motor height that way. Once it was at its smoothest point, there was no lateral play with the bevel gear. It was nice and snug. That' the best I can explain it. I'm not really a gun doc in any way. I just know that it worked.

__________________

|

|

|

|

|

|

|

#28 | |

|

Quote:

- The bevel sits on top of the pinion so there's no play downwards. - There's some play in in the upwards direction because the top half isn't shimmed to take it out (which works good for you in this case) - When the motor/pinion is installed the bevel in a sense shifts upwards and self corrects the meshing between the pinion/bevel. It can do this because the top half isn't shimmed. So what I think you could do (but I think is probably pointless) is shim the bevel gear even higher. But sounds like everythings meshing and in place nicely so I wouldn't bugger with it.

__________________

Ronin 49 Team Member |

||

|

|

|

|

|

#29 |

|

Tys

|

I've got some test mechboxes (sorbo and PP parts testing) that I'm working with. I'm going to set it up in a little M4 with a 7 in outer barrel...if I'm lucky I'll just cut down and recrown the barrel right on the gun...or else I'll just pop the inner out, chop/finish it and put it back in.

It's a test to demonstrate what velocity drop you can expect by solely switching barrel lengths. All shots will be semi auto. Right now the mechbox is setup with an M4 ported cylinder...I might switch to a full cylinder...but the objective isn't to "tune" each barrel length...but just compare between them. Not sure, still just getting setup to test. Tys |

|

|

|

|

|

#30 |

|

Tys, that'll work pretty good then with the stubby outter. Didn't even think about that. I would suggest you go with a full cylinder so you don't "starve" the longer barrels for air.

Well yesterday I got to compare my buddy's Modify Torque up gears (caged) directly side by side with his regular ratio ones - I'll probably never touch a hi-torque gearset again and neither will he! The tooth profiles and pitches were so different its amazing. Especially the spur gear - the teeth were so small I can see why guys seem to strip that gear all the time! I also got done my my BB weight vs velocity testing yesterday too. Tested 2 velocities (~320 and ~385 - both on the same gun) and with 6 different weights of BB's. All I'll say for now is no one will believe my results! I wouldn't either unless I did the tests myself.

__________________

Ronin 49 Team Member |

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|