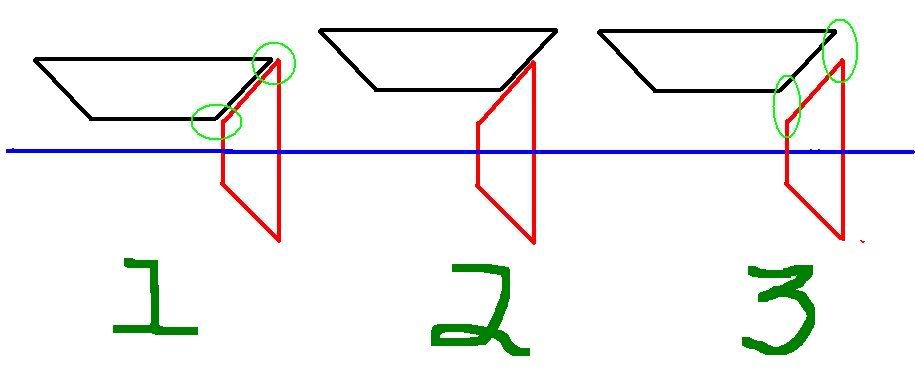

The whole internet discussion thing is brutal to try and descripe things! A picture's worth a thousand words (well maybe not this one):

Quote:

Originally Posted by m102404

Now imagine your reference picture with the pinion gear still fixed in the same horizontal left right axis. But now the bevel gear is raised up on it's vertical axis. As you described, the two angles are the same between the teeth, but now with the bevel moved up, there's no way the pinion gear can advance far enough to the left to fully engage the teeth of the bevel gear. It's essentially forced to be "backed off". But unlike the previous paragraph, the tooth to tooth contact surface isn't just at it's edges...but rather the teeth are jammed together.

Tys

|

I think I followed you until there. I think you've got a good understanding of what's going on. Let's see if I can try and describe it and see if we're on the same page. Maybe we're in different books....

Reference:

Black - bevel gear

Red - pinion gear

Blue Line - axis of motor (to show reference, it shouldn't change unless you run your wires wonky and tilt the motor)

Green Circles - just to show that ideally you have the leading/trailing corners lined up for maximum tooth contact

Note that the 2 surfaces are ALWAYS parallel to each other (well ideally...my paint skills are terrible!).

Tight meshing gears (without jamming things) are nice and quiet ones. They need proper backlash and the same tooth profiles (ideally) to get this.

#1

Proper bevel/gear meshing and alignment. Here the bevel gear is shimmed to the right heigh. The leading edge of the pinion is NOT past the inside edge of the bevel.

You can see that if you move the pinion from Right to Left the pinion teeth will mesh deeper until the leading edge and inside edge are vertically alined - past this point and then the mechbox will start to jam up (assuming the pinion is cannot move virtically upwards). I usually try to adjust the motor height to get it to jam, then back it off until it sounds nice to get maximum tooth contact. I too have noticed lots of really warn pinion gears with the top 2/3 warn far down and the bottom 1/3 not touched.

#2

This is a situation where the bevel is not shimmed and can move in the verticle direction (as you described in your test). You can see that the bevel won't start moving upwards until the leading edge on the pinion moves past the inside edge of the bevel.I don't know why I made this picture??? haha

#3

This is the situation where you have shimmed the pinion gear up higher. Now the tooth mesh is crappy, however you increase the backlash. So for properly designed bevel/pinion this would be louder than it should be but can make things quieter for improper ones as it increases the backlash.

So, did I just regurgitate most of everything you just said? :banghead:

I can't try to shim the bevel higher on my buddy's gun as it is the drop in gearset (caged).